DRILL AND BLAST

As a drill and blast industry specialists, our aim is in delivering the best production drill and blast contract services.

Civil Blasting

A key pillar of Singapore’s impressive growth record was its infrastructure. Upgrading of public housing, road and rail network, underground utilities network and port facilities are regular features in Singapore’s infrastructure development. Often then not, new developments and projects are sprouting up in the build-up areas and populated neighbourhoods which requires careful planning when it comes to blasting works. During civil engineering works, such as blasting and excavation, noise and vibrations are generated which can affect residents and industrial activities in the vicinity. With the right mind-set, risk management, latest blasting product / systems and backed with the right personnel and experience, the works can be well executed with the minimal inconvenience or disruption to the neighbouring industry.

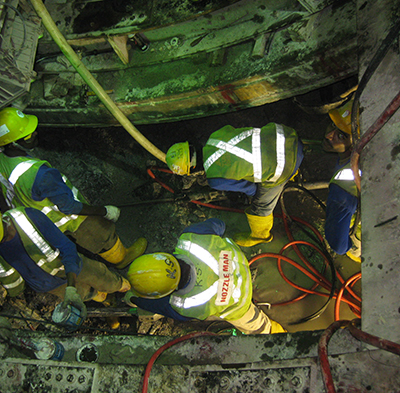

Shaft and Tunnel Blasting

While TBMs are used in many civil tunnelling projects, the initial underground excavation for the shafts and tunnels in rock is undertaken using blasting techniques for the launching of the TBMs. These underground works require special blasting techniques and systems to effectively excavate the rock. Major projects in Singapore such as the Jurong Rock Cavern, the underground MRT lines, the Deep Tunnel Sewerage System and the Cable Tunnels require the removal of big volumes of rock during construction.

Quarry – Open Blasting

Quarry blasting for aggregates or road way construction leading into the quarry for efficient land use and space management are other reasons for blasting to effectively break large volumes of the rock in our land scarcity island. Though such blasting technique are rare these days, other similar approach of blasting large rock volumes in a single blast are undertaken for new housing and MRT projects. Such large scale blasting is perhaps one of the most challenging aspects facing the industry as population and urbanisation has brought it closer to the operating sites where large volumes of rock are encountered.

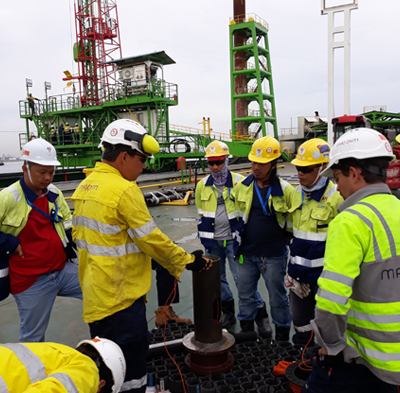

Under Water Blasting

In some cases where dredging is met with extremely hard rock formation, underwater drilling and blasting operations are performed usually for harbour deepening, pipeline construction and extension of ports. With relevant experience in this field of work, we can provide the expertise to undertake the blasting works with our latest explosives products and systems.

Other Blasting Activities

Apart from construction blasting works, explosives are also used for geological / site characterisation projects normally termed as “seismic survey” works using explosives as a medium for the exploration of the earth’s sub-surface from the reflected seismic waves generated from the blast. Usually small charges are used for such projects and initiated individually over large span area or termed the survey lines. Other similar test are also carried out for liquefaction and calibration test based on the clients request.